The masterpieces that leave the Feadship yards are often defined to a significant extent by their innovations. Of course, some of these innovations are more visible than others. The most impressive feats find their origin in sophisticated out-of-the-box thinking and a mentality of getting things done, no matter how complex. From its earliest days, Feadship has defined superyachts by blazing new trails in concept, quality and finish. The variety of solutions and range of technological possibilities are a major selling point for our clients.

Innovations don’t just pop up, however. They rest on profound ideas, new principles, proven concepts and clever prototypes. Our innovation programme Headway scouts out as-yet immature technology developments from fundamental academic research and translates them into à la carte designs. Advanced monitoring of our final products and external partnerships ensures the highest quality for all our systems. Considerable resources are invested in continually raising the bar, bringing new ideas to life and adopting rapidly advancing technologies.

Technology in practice

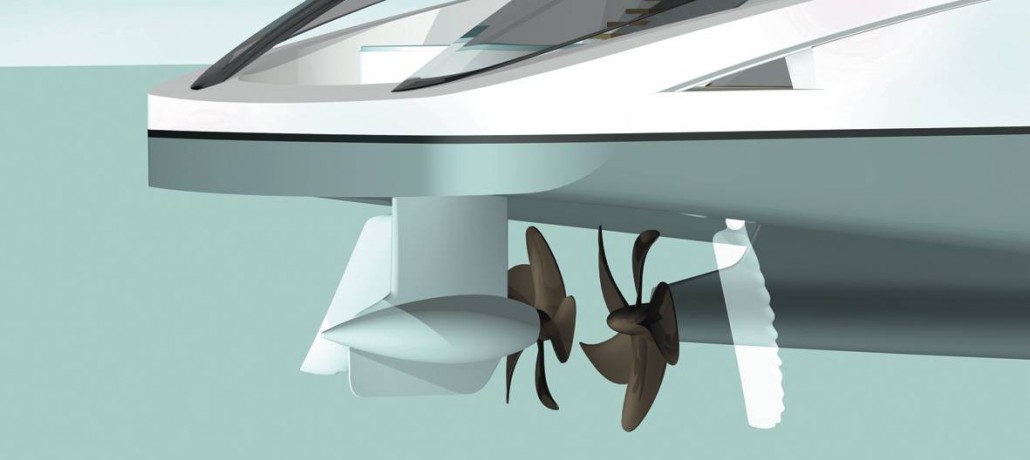

The enabling mechanism in Feadship’s pure custom design and construction are our multidisciplinary capacity and market leading expertise. From steel, carpentry and paint craftsmanship to the best creative designs and after-sales service, we have the most effective innovation, finest resources and smartest ideas. While many of our developments may be hidden from view, they nonetheless provide the highest design freedom and optimise the experienced quality and comfort. At the same time, some of our innovations are highly visible to the yachting community. One example is the underwater loungeconcept, which may well find its way to the market one day. Perhaps most striking is the short time it took to translate the Breathe concept from 2010 to the actual build of the award-winning Savannah launched in 2015. The advanced hull design, smart hybrid powering & propulsion arrangement and nemo lounge were all inherited from the Breatheconcept.

No less of a great achievement is the bespoke wooden interior of another award-winning Feadship, Symphony. In order to be able to charter 36 guests instead of 12, the interior had to be reinvented in compliance with the Passenger Yacht Code: for instance, the choice of base and finish materials was restricted by fire safety codes. Combined with a specific interior design and material selection brief from the client, this was a serious challenge to our creativity and required rapid transfers in knowledge from engineer to carpenter. The pinnacle of the effort was passing fire tests with our own wood veneers, ranging from grass-like palm wood through to oily teak, each requiring a different treatment to manage the spread of flame, smoke and toxicity.

Over the horizon

What does the future hold? Advances in technology will bring opportunities for more efficient and comfortable operation by means of adaptive intelligent control. This, in turn, will lead the way to autonomous operation of yachts, allowing crew to concentrate on hospitality. More smart materials, topology optimisation and additive manufacturing technology will make their way to our yards, enhancing the uniqueness of our products even further.